Special Earthquake Engineering Project of the Year Award (2005)

In October 2005, Phase 2 of the Golden Gate Bridge Seismic Retrofit Construction Project was recognized as The Special Earthquake Engineering Project of the Year by the San Francisco Section of the American Society of Civil Engineers.

According to Deputy Bridge District Engineer and Phase 2 Project Manager Ewa Bauer, "The credit goes to our project construction management team for understanding complex design and construction issues and enabling a collaborative problem solving; to the designer for developing innovative, efficient and cost-effective retrofit design; and to the contractor for building this technically very complex project despite harsh weather, restricted space and access and numerous permit restrictions."

Outstanding Civil Engineering Achievement Award (2007)

The Golden Gate Bridge Seismic Retrofit Phase II, South Approach Structures Project was named the recipient of the 2007 Outstanding Civil Engineering Achievement (OCEA) Award by the American Society of Civil Engineers on April 25, 2007.

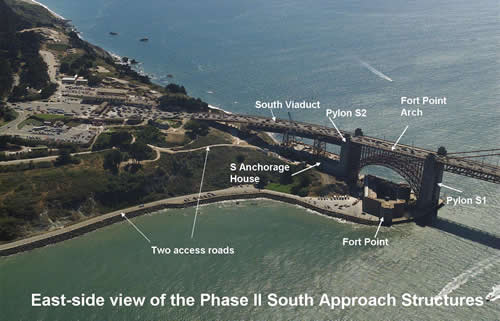

The majestic Golden Gate Bridge spans the only Pacific Ocean entry to the San Francisco Bay and sits between two major earthquake faults, San Andreas Fault seven miles to the west and the Hayward Fault ten miles to the east. The Phase II Project is the most complex part of the Golden Gate Bridge Seismic Retrofit in terms of design and construction. It is an undertaking of magnitude and complexity that can only be compared to the original Bridge construction. “This project met the challenge of complying with modern engineering standards, while preserving the historic and architectural value of the bridge’s 70-year-old structure,” said ASCE President William F. Marcuson, Ph.D., P.E., Hon. M.ASCE. “In addition, the bridge remained open to traffic at all times during construction. In every way this is an exceptional example of everything the OCEA award embodies.” The Golden Gate Bridge Seismic Retrofit Phase II, South Approach Structures Project encompasses the structural retrofit of five structures at the south approach: the south approach viaduct, south anchorage housing, two south pylons, and the Fort Point arch. These structures are located at the edge of the Pacific Ocean and directly adjacent to and over the historic Fort Point, built in 1800s.

The Bridge was originally designed to withstand lateral forces of approximately 7.5% self-weight. The Phase II Project design criteria required that the retrofitted structures withstand an earthquake imposing lateral forces of up to 68 % to 220% of the structures’ self-weight.

Golden Gate Bridge Seismic Retrofit Phase II, South Approach Structures Project team includes:

-

Project construction management: Bridge District, HNTB Corporation and The Duffey Company’s staff;

-

Project designer: Jacobs-Sverdrup/Thomas Jee & Associates;

-

Constructor: Shimmick Construction/Obayashi Corporation, a Joint Venture.

The best evidence of the team skills to deal with challenges associated with such a complex undertaking is that the Phase II seismic retrofit measures are now in place and their construction was completed under budget. The retrofit design was a combination of sound, practical and innovative engineering with attention to constructability under continuous traffic.

The retrofit techniques used—many of which had never before been employed—greatly decreased the magnitude of earthquake-induced forces in the structures, thus significantly reducing the extent and cost of the retrofit. Design details were configured to fit the highly variable, originally constructed details without altering the Bridge’s aesthetic values.

Phase II was built in the harsh marine environment where dense fog, strong winds and crashing waves are a norm. Great attention was given to minimize construction impacts on the surrounding environment. Construction operations and materials delivery were staged for continuous flow of vehicular, pedestrian and bicycle traffic across the Bridge and on narrow roads of the surrounding national park. Platforms installed on the arch shielded Fort Point from damage. Construction workers were shuttled to the site to minimize construction traffic impacts on local roads.

The centerpiece of the Phase II retrofit was the strengthening of the two massive 220-foot-tall hollow concrete south pylons. The pylons were amended so they could dampen seismic energy through rocking motion. Pylon foundations were fortified by expanding their depth by 20 feet upwards and by anchoring each pylon to the bedrock with 150-million pound capacity tiedown system drilled to a depth of 100 feet. Pylon walls received an “armor” of 5.5 million pounds of interior and exterior steel plating spliced with over 7 miles of welds. The exterior and interior plates were tied with 30,000 steel rods inserted in holes cored through the concrete Pylon walls. Finally, a concrete cover with a rough lumber architectural finish was cast over the exterior plating to replicate the original concrete surface of the Pylons.

The steel Fort Point arch structure was modified into a huge energy damping element. Designed specifically for this application, the Uplift Guides with 1-inch vertical uplift capacity and the Impact Force Reducing Devices were installed at the arch bearings, and the Energy Dissipation Devices utilizing abrasive friction were placed at the interface with the south pylons to disperse the shaking energy of the arch. The original riveted connections of the arch were enlarged and transformed into modern bolted connections. Steel members were strengthen with tons of added steel. This “surgical” work was done according to special details engineered to preserve the structure’s integrity and capacity to carry traffic at all times. To complete the system, “breakaway” seismic isolation joints were constructed in the roadway deck at each end of the arch to enable the arch to move independently from the adjacent pylons during an earthquake.

Another complex undertaking was total replacement of the ocean-facing 235 feet long and 90 feet tall west wall of the south anchorage housing. The new wall was cast in forms that replicated the original rough lumber finish. In all, the anchorage housing underwent extensive internal retrofit.

The south viaduct was transformed into a modern steel structure. The supporting steel towers and bents and the bottom lateral bracing were completely removed and replaced. To replicate the original laced look of the structure, new steel members with laser cut lacing-like perforations were designed, fabricated and erected. Isolation bearings were installed atop the new towers and bents, and the “breakaway” seismic isolation joints were installed at both ends of the viaduct.

The importance of the Phase II effort cannot be overstated. The Bridge is the only direct transportation link between the San Francisco Peninsula and counties of the vast Redwood Empire to the north. Interruption of the traffic flow across the Bridge would result in extreme losses to the region’s economy. The Bridge is a worldwide recognized symbol of United States engineering and outstanding bridge architecture. This international icon is visited every year by more than 10 million tourists from all over the world. The Phase II Project is critical to preserving the Bridge for future generations.

The Golden Gate Bridge, Highway and Transportation District, which is Special District of the State of California, owns and operates the Golden Gate Bridge. The Golden Gate Bridge Seismic Retrofit Project is being undertaken in three phases. The first phase retrofitted the north approach structures and was completed in spring 2002. The third and final phase will seismically retrofit the north anchorage housing and associated pylons and the main span and towers.

Established in 1960, the American Society of Civil Engineers’ (ASCE) Outstanding Civil Engineering Achievement (OCEA) Award recognizes projects for their resourcefulness in addressing planning and design challenges, impact on the environment, pioneering uses of materials and techniques, construction innovations and contribution to the well-being of people and their communities.

Previous winners have included the relocation of the Cape Hatteras Lighthouse, the Trans-Alaska Pipeline and the World Trade Center Towers. Founded in 1852, the American Society of Civil Engineers represents more than 140,000 civil engineers worldwide and is America's oldest national engineering society. For more information, visit www.asce.org.