By mid-1935, the north and south towers stood ready to support the two main cables. Each of the cables measured a little over 3 feet (about 1 meter) in diameter and weighed 12,000 tons. They were far too heavy to carry across the Golden Gate Strait on barges and lift up to the tops of the towers.

The cables were constructed high in the air using a process called cable spinning, which was invented by John A. Roebling in the 1800s. The company he founded made cables for the Golden Gate Bridge.

To spin the cables, workers pulled a wire, about as thick as a pencil, from the concrete anchorage at one shore, up and over both towers, and on to the other anchorage. The wire was then secured and sent back. It took many back-and-forth trips to place the 27,572 wires that are in each cable. Individual wires were grouped into heavier strands and compacted together to form the finished cable. The spinning of the cables took just six months and nine days, setting records for speed and efficiency.

The entire weight of the roadway deck crossing the Gate could then be suspended from the two cables – that’s why it is called a suspension bridge.

More Images

|

Known as spinning, thin wires were drawn back and forth across the strait by steel wheels.

Image courtesy of the San Francisco Historical Society - Huggins Collection - CHS.Huggins.012

|

|

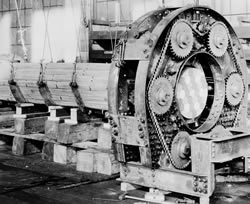

A hydraulic press compacted the thin wire strands into one large cable.

Image courtesy of the San Francisco History Center, San Francisco Public Library

|

|

Workers tighten bolts to clamp a band to the main cable. Steel suspender ropes were later placed over the top of the cable band and extended down to support the deck structure.

|

|

A popular exhibit at the Bridge is this full-size cross section of the main cable, clearly showing the 27,572 parallel wires.

|

Explore this Topic Further

Spinning the Cables from PBS American Experience (grade 3 to adult)

Read an understandable description of the innovative process developed by the John A. Roebling’s Sons Company to spin 80,000 miles of steel wire into the 3-foot (a little less than one-meter)diameter main cables.

John A. Roebling Biography from the Roebling Museum (grade 3 to adult)

John A. Roebling was a civil engineer who significantly advanced the state-of-the-art of suspension bridge design and construction. The company that he started provided the steel and developed the technique for spinning the cables.

History John A. Roebling’s Sons Company from the Roebling Museum (grade 3 to adult)

The John A. Roebling’s Sons Company based in New Jersey became the largest supplier of wire rope in the world. Today, it is the site of the Roebling Museum.

More photos from the Golden Gate Bridge, Highway and Transportation District (GGBHTD) (all ages)

See a few more photos of the cable spinning.